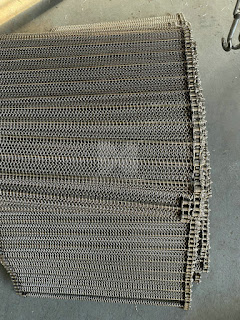

wire mesh liner for heat treatment by Qingdao Hexin Machinery Co.,Ltd.

Heat-resistant steel mesh baskets can generally be selected according to the steel type and the working temperature of the components. The principle of selecting heat-resistant steel welding materials is: the alloy composition and performance of the weld metal are consistent with the corresponding indicators of the base metal. Or it should meet the performance indicators proposed by the product technical conditions. In order to improve the thermal crack resistance of the weld metal, the carbon content in the weld should be slightly lower than the carbon content of the base metal, and should usually be controlled between 0.07% and 0.15%. Due to the joint action of carbon and alloying elements in steel, heat-resistant steel is easy to form a hardened structure during welding, and the weldability is poor. For this reason, heat-resistant steel generally needs to be preheated before welding, and tempered after welding. Stainless steel mesh baskets are made of stainless steel, 304, 304